1.1 Logistic Management

There has been a significant revolution in logistic management since the 1950s. Logistic management has become a key element in trade during the past decades due to the trend towards Globalization. In order to maximise efficiency in distribution and increase competitiveness, industries try to make the best possible use of logistic management.

The Council of Logistic Management (1991) defined logistic management as follows “part of the supply chain process that plans, implements, and controls the efficient, effective forward and reverse flow and storage of goods, services, and related information between the point of origin and the point of consumption in order to meet customers’ requirements’. Five key terms have been used by Johnson and Woods (Cited in Tilanus, 1997) to define logistic management. These are namely; logistics, materials management, inbound logistics, supply chain management, and physical distribution. The entire process of moving products and in and out of the business is referred to as logistics while materials management is related to the movement of materials within the firm. On the other hand, inbound logistics consists of the movement of materials from its source and physical distribution is the process of moving goods from the firm to the customers. Finally, supply chain management is the total communication network enabling the logistics process.

Logistics management is a function bestowed with great importance to oversee the success of a company’s operations since it has a direct impact on the end results. Logistics process are essential in key business process such as customer satisfaction which is of more importance when compared to other marketing techniques such as price reductions. Professionals specialised with logistics management should picture themselves as potential customers to the company and aim to improve value addition to their customers.

1.2 Key activities and responsibilities of a logistic manager

Logistics management is a broad area which encompass different activities undertaken to facilitate smooth operations within a company. It entails the flow of goods and materials in a business setting .Below are some of their key activities done by logistics managers as enshrined in a company policy.

1.2.1 Traffic and transportation

This is the process whereby goods and services are moved physically. Transportation plays a critical role in the supply chain as it can be associated in high costs. The logistics mangers are tasked with choosing the most cost effective combination of transport and improve a value to both customers and the company. The main transportation channels are: railway, sea, pipeline, air, road, etc.

1.2.2 Warehousing and storage

Warehousing involves activities such as storing of goods, receiving of material to be shipped from production and distribution points’. Most importantly, it includes the management of the human resource.

1.2.3 Material product handling

Allocation and movements of materials and products and its distributions within the warehouse. This involves activities such as order procedures, shipment activities within a warehouse. Coordination by e logistic management of the equipment’s and the storage options to be used in product handling.

1.2.4 Inventory control management

Among the key functions of a logistic manager is to ensure that inventory levels are adequate and accurate. The inventory levels are subject to inspection and replenishment by a number of activities such as monitoring the production schedule, monitoring shipments or placement of new orders. The accuracy of the inventory is subject to check against records within a system. This is whereby the logistics managers are entitled to do a physical inventory check and compare with the systems data. On an situation whereby there are instance inaccuracy, there will be need for system update and reporting. The resulting measure can be to replenish the inventory if needed. Having a proper inventory control is key as it leads to cost reduction.

1.2.5 Demand forecasting

Forecasting is a key aspect which leads to efficiency of inventory. There is need for forecasting to be accurate and reliable. The logistics managers are supposed to develop forecasts in conjunction with marketing department with high level of accuracy, this is because high inventory costs are associated with poor forecasting.

1.2.6 Procurement

Procurement as a process is tasked with negotiation of contracts, deliveries and the process of picking a supplier. The logistic manager is a company is tasked with overseeing transportation activities which are based on cost of the materials needed for production and location.

1.2.7 Customer service

Customer service is one of the most important function under the logistic manger responsibilities. The logistics manager has the mandate to ensure that customers receives a product within the stipulated, place and with uncompromised quality. There is need for the logistic manager to be concerned with aspects such as inventory level and location and ascertain that deliveries can be made within the set timelines.

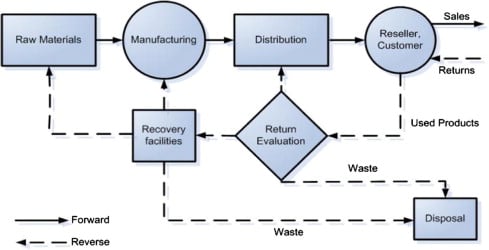

1.2.8 Reverse logistics

The main aim of reverse logistics is to facilitate cost reduction by ensuring proper management of resources is in place. Among the activities included in this areas are the return, recycle, and reuse policies.

1.2.9 Protective packing

Logistics managers are supposed to come up with proper packaging policies, this is because different modes of transportation will need varied packaging for a product. The packing method to be chosen should be able to mitigate any risks that would occur during transportation and storage phase.

1.2.10 Information maintenance

Information management is a process that is critical to a company. Information can be attained from different production or business practices. Types of information likely to be attain include maintenance and data storage, analysis control data and maintenance data. The data is critical as it enables key decisions to be undertaken.

1.2.11 Salvage and scrap disposal

The disposal of salvage or scrap items is a task that is overseen by logistics managers. Logistics managers need to ensure proper handling of these items by either disposing them or selling to specialized companies. This is more important as there is a growing campaign on environmental consciousness.

Question 2

Define purchasing, procurement and strategic sourcing methodology. There are some guiding principles for strategic sourcing that are recognized as key drivers to ascertain value – what are they and give a brief explanation of each. Supplier relationship management (SRM) is an important process from an organization’s perspective that is used to support procurement efficiency and improvement. There are some key operating principles that should to be used in this process. Discuss what they are and explain each.

2.1 Purchasing

Purchasing generally is defined has the practice of procuring or acquiring of goods and services from different external agencies to help in accomplishing certain goals and objectives. Therefore, purchasing departments in organizations are set organize for the supply of items, spares, materials, raw materials, and services which are needed with the organizations so as to produces the required and desired finished products to some external organizations (Chand, 2018). Mostly, the purchasing material and items are always specified to the required plus desired quantity that is set available and approved within the timelines for a competitive pricing. Likewise, purchasing can be said to be procuring of supplies, materials, tools, machines and services needed for operations, productions and maintenance in manufacturing firms.

Other scholars in the field of supply chain management such as Walters has referred to purchasing function as the procurement through the means of purchase regarding getting proper machinery, equipment, materials along with supplies which are stored and later used in manufacturing of products (Coyle & Coyle, 2009). Subsequently, products are marketed in desired quality and quantity within the required time and desired market price based on the reliable with quality wanted. As such, purchasing operates within the scope of marketing in procuring/acquiring of goods and services for the desired quantity, quality on lower price range in desired timelines. For such, markets suppliers would offer standardized products based on competitive pricing and therefore, the ones who offer best affordable prices are chosen (Stolle, 2008). Moreover, purchasing is related to managerial aspect that is far beyond just buying or acquiring. It is constituted of research and development (RD) where there is proper selection of items (materials, equipment and raw materials), undertaking a follow-up to guarantee timely delivery, having regular check-ups to warrant quality and quantity is obtained; all this which are aimed at reduces loses and increasing profitability of the organization.

2.2 Procurement

On the other hand, procurement definition is closely related and frequently used wrongly interchangeably. Procurement has a wider array of definitions, and according to WordWeb dictionary, it would refer to the act of getting or obtaining possession of something, such things as supplies, materials, items and so on. From Merriam Webster Online dictionary, it refers to an act or a process of procuring whereby supplies, materials and other items are obtained by the government (Military) (Merriam-Webster. 2018). Conceptually, procurement refers to the principal function, which describes the processes and activities of acquiring or obtaining of goods and services. Contrasting with purchasing, procurement constitutes of the establishment of key sourcing activities, requirements like vendor evaluation, market research and most importantly negotiation of contracts. Additionally, it basically involves purchasing activities needed in ordering and receiving goods.

Quite a number of companies use procurement since it is one of the effective tools in improving customer’s satisfactions and cutting cost. Anyway, the term procurement can refer to the involvement of the development of need of their specifications. Further, it involves managing supplier’s negotiations, value analysis operations, marketing research, contracts and the idea of managing supplier value. To add, the terms is simply the acquisition process employed in securing goods, services and other tasks from external sources such external examples include company, organization, individual, charity and institutions (Turner, 2011). In most cases, before agreement being reached, the external sources need to provide appropriate solutions to the problems linked. The idea of cost and pricing decision require being agreeable. Procurement from the larger corporates and public organizations always try to promote greater competitions and choice through acquisitions and procurement programs. For both purchasing and procurement, both require choice and quality, which far helps businesses and ultimately benefiting everyone in the organization.

2.3 Strategic Sourcing Methodology

As seen from most scholarly journals and books, strategic sourcing methodology refers to where an organization begins to search for quantum savings from their suppliers in supply chain management. It is defined in institutional terms of procurement as the process of continuously improving and re-evaluating the purchasing operations as well as activities in the organizations. In addition, in the services sector, it refers to the services solutions which at times known or referred as strategic partnership where they are set and customized to meet customer’s personal needs. Based on the production environs, the terms regularly is considered has one constituent of supply chain management.

Nowadays, supply chain management experts have defined it in quite a number of ways, which have differentiated procurement and strategic sourcing. In fact, procurement as seen earlier supports operations, which are tactically based on daily transaction like ordering and issuing of purchases, related to suppliers. While on the other hand, strategic sourcing ideally represents the plans, contracts, negotiations, infrastructures, supplier development and outsourcing models. Additionally, there are different models, which exist regarding to strategic sourcing methodology. However, organizations, which try to use this philosophy, would share certain elements or works of their own performance. Strategic sourcing methodology would be applied and implemented with the objective and goals relating to purchasing savings with other distinctive of business.

In general, strategic sourcing methodology is the process of establishing certain channels within supply chain in order to lower the total cost and the purchasing price. It expands all through the traditional purchase activities, which embrace the procurement phase; that is through specification up to receipt and the paying of goods and services. It is important to note that strategic sourcing mainly focuses on reducing cost and it is based upon a foundation built to focus on long-term win-win aspect relation on important suppliers to offer the buyers a competitive edge (In Edquist et al. 2014). The relationship nature is meant to give emphasis to the success factor of strategic initiatives. Finally, it is always critical for both suppliers and buyers work together and try sharing information, which will help in identifying the opportunities that are significantly help in increasing the savings over time.

2.4 Key Guiding Principles for Strategic Sourcing

Most excellent companies and organizations acknowledge the fundamental importance of strategic sourcing as the key driver with regards to value creator and likely consider it as the overall integral part of the strategy for their growth. For a company to emerge as an excellent in procurement, it needs certain guiding principles, which will enable them to have an efficient and effective strategic sourcing and thereby help in transferring value all through the supply chain to reach customers from the suppliers (Lunney, 2018). Here are some of the principles that help to ascertain value in the organization and create winning success.

2.4.1 Governing Committee

In order for the strategic sourcing managing team to succeed, it would be important for the organization top level to support them. The best organizations globally have created sanctioned supply management governing council to check and oversee various task relating to outsourcing team. From the team’s members, they would be influential in business activities and supply chain such as in providing goals, direction and aligning o the company’s strategies. Additionally, such committee would have great impact in decision-making and thereby remove certain barriers whereby the sourcing team can able to attain their goals and objectives.

2.4.2 Research

The organization should always try to conduct both data collection and its analysis. Such researches can be conducted through having internal sources of data like prices paid, number of suppliers and existing contracts, business activities utilizing certain products and services. On the other hand, the external sources of data constitute of competitive benchmark, marketing information, and the financial aspect on suppliers; furthermore, always remember to perform global research and for best effective strategy, this global view would be required (Wisner,Tan, & Leong, 2016). Through performing global research for example, will help to revealing new suppliers and thus be benchmarked as a world class performing company. For instance, sourcing from a country such as USA would help in global benchmarking in that, improve the drive and local and national suppliers.

2.4.3 Focusing on Total Cost Ownership

Cost and pricing is key component in sourcing and members should always be focused in their acquisitions. The decisions made in strategic sourcing need trade-offs based on the price and cost. To have a valued sourcing strategy, it is important to identify the means, processes, performance and practices linked to working of suppliers. Organizations can ascertain the opportunities for collaborations resulting in total price and cost reduction through thinking with regards to total acquisitions cost and price.

2.4.4 Establishing a Cross-Functional Teams

Even though most of the organizations employ cross-functional teams in their development of strategic sourcing, quite a number are not reliably involved like manufacturing, finance, and so on. It important to create sourcing strategies and make you it should be viewed as a future endeavors and rather not a purchasing task. The cross-functional team helps in creativity through having diversity sentiments and building of organization in terms of buying-in within the sourcing process.

2.4.5 Established Enterprise Alignment

The stakeholder’s and internal user involved in sourcing development strategy and supplier’s selection are highly essentially encouraged and recommended. In case there is need to drive compliance through having new contracts and achieving the true valid potential of deals, it means your new suppliers must not view their stakeholders as procurement suppliers and rather they should be regarded as their suppliers that have been collectively been chosen (Wisner,Tan, & Leong, 2016). Although, in procurement departments the idea and perception of suppliers exits, particularly if you have expelled a widely held incumbent, such stakeholders may try an exploit the reasons why selecting the suppliers would be a resulting bad decision. Always at the course of sourcing processes, it is important to communicate to the internal stakeholders of the company and offer updates and solicit involvement regularly. Most company stakeholders have authority in achieving cost saving potential and therefore can make prevent others from reaching their goals. Lastly, in regards to the value established enterprise, it is important to buy-in the working harmony.

2.5 Supplier Relationship Management (SRM) Key Operating Principles

There are many factors considered in todays’ global economy when managing and choosing a supplier who best suites and quickly overwhelms. It is with greatness that the new technologies have help to simplify and automate the processes and thereby making quick and faster informed decisions regarding the suppliers, which are quite impressive. Organization or companies, which focus on supply relationship management, lead their peers to a valued, derived toward supply base (Rizza, 2018). Simply, Supplier relationship management involves disciplines involved in strategic interactions, planning, and management with the third parties tiers in the organization who supply goods and services thus maximize the values of such interactions. Generally, it involves creating collaborations relations with the key suppliers so that to uncover reduced risk and realize new value.

Some of the principles basically used on Supply Relationship Management in support of efficient and effective procurement are:

2.5.1 Focusing on the relationship

Nowadays, around the world the idea of supply base is just about the about consolidation of relation which can break or make your business. Trying to earn your suppliers trust and honesty is important therefore communications, listening and getting involved to their concerns is fundamental and is ultimately provides them a conferred partner within the business.

2.5.2 The expectations changes

Procurement is to understand their expected bolster and vulnerable teams/groups for success (O’Brien, 2018). Teams applying greater emphasis on quantitative and qualitative supplier data study are faster in identifying the risk, weak spots and opportunities within the global chain thereby able to improve the plans and strategies required in managing suppliers and finally continuity of the business success.

2.5.3 Mutual benefits

Being aligned to your suppliers as a company and having better treat towards them can highly results improved success factor, reduced risks, enhanced innovations and collaborations (O’Brien, 2018). It is highly been noted from a number of studies that having top procurement teams those which have successfully been aligned to the key suppliers have greatly improved the capabilities of quality, innovations, cost, reliability and the agility to minimize the risk factors. Additionally, greater values in businesses cannot be easily achieved if one is operating individually.

2.5.4 Delivery of big opportunities

Successful Supplier Relationship Management produces quicker time to market, compete, transactional efficiency, having financial gains, and risk management of which all are not only contributed towards bottom line but allowing ones delivery on cutting edge and quality products, and basically being ahead on the market.

2.5.5 Simplifying processes through technology

The critical aspect of supplier relationship management is having greater systems in the organizations, which allow and make suppliers easier to analysis as well as view the risks factors (O’Brien, 2018). Furthermore, the technology used offers one a full visibility towards the supplier base thereby giving a clear and detailed picture/ view of what has influenced the supply chain and one will be able to solve or mitigate the risk.

Question 3

Reverse logistics and the management of returned or used merchandise is a growing problem among manufacturers today. Explain how this can be managed efficiently. Reverse Logistics and closed loop supply chains are sometimes used interchangeably as synonyms, but there are differences – identify and explain the key differences.

3.1 Introduction

Reverse logistics refers to the supply chain process of returning products from end users back through the supply chain to either the retailer or manufacturer. Reverse logistics has received much consideration in supply chain management because it mirrors company’s positive influence and its relationship with the customers. In addition, the term results in major cost repercussions for both the suppliers and the company/organization. For instance, the retailing companies, which lack adequate competence in implementing reverse logistics plans/strategies greatly, experience increase financial and management problems towards improving customer services (Fernández, 2004). Furthermore, the idea of reverse logistics has led to competitive need within the overall supply chain plan. Thus, when reverse logistics is managed well it would help companies in achieving cost savings in given areas like transportations, inventory carriage, efficiency in terms of customer improvement and concerning waste disposal. Ideally, in the past most companies employed forward logistics practices only. However, nowadays organizations supply chains bit by bit have integrated more activities and operations than the concept based on forwarding logistics like product and services recovery. You can explore a comprehensive CPC course online at ntponlinelearning.co.uk to gain insights into reverse logistics and its significance in modern supply chain management.

3.2 Reverse Logistics

The term refers to the management of returning items/materials from customers that constitute reengineering, disposal of waste, restoration, recycling within an eco-friendly way. The whole idea behind reverse logistics is to reduce control of cost and on the other hand, maximizing the valuable goods and products disposed of (Robinson, 2018). Reverse logistics hasten the logistics cycle. Furthermore, reverse logistics is simply an opposite of logistics management where goods, items, and materials move in different directions in supply chain meaning it moves from customers and back to suppliers.

The causes to returning the products and goods to the company are such as damage products, exchange of impairments, warranty failure, product recalls, having reusable packaging, damages goods/products, and upgrades and so on (Robinson, 2018). Returned goods/products by all accounts to be dealt using and looked in the best way as possible.

3.3 Concept-Based on Reverse Logistic

The perception of Logistics Management begins from the definition of reverse logistics where it refers to supply chain process relating to planning, implementation, cost-effective, control efficiency of the flow of materials, finished goods, and information-driven from the point of consumption at a given point to for another determination like recapture as well as being able to create value. When a product, goods or items are reverse/returned to the company, they would be determined through checking their conditions, establishing if such items can be sold and even sent back to those vendors (Magazine & Fernandez, 2018). Another decision is to check for the particular areas or places to sell the products; for instance, selling off items to a broker who observes the centralized reverse flows allowing employees mainly to focus on the specific reverse logistics process. In addition, reverse logistics is not only about returns based on backward flow but also about deals with both backward and forward information flow thereby enabling lean and green logistics that brings about increase competitive edge.

Ideally, reverse logistics plays a critical role in the product lifecycle in addition to the corporate strategy and plans that the company cannot ignore to attain. Based on this concept, the most important role of reverse logistics is helping in obtaining and understanding the problem as well as knowing the patterns in regards to the faults/defects thus, making way to decreasing some reversed products (Niroomand, 2018). Moreover, within its domains, some of the products reversed are processed and they emerge as the vital element that influences the purchasing decision, which touch the customer and hence is viewed, has the competitive advantage based on the processes of product return.

In terms of retailing perspective, the term reverse logistics is greatly a major concern that relates to the managers because of the shrinking limits that are prompted by the current sales loss, cost of storage, the recoverable potential, product value and certainly the important aspect to channel partners and customer’s relation (Aït-Kadi, 2012). Likewise, it encompasses certain areas like a place where products are sold as soon as they are returned, the reprocessing process, buyers and sellers relationship, also the technologies employed to support the reverse/return process. To have a successful reverse logistics process, management in the organization has to initiate and develop a logistics plan that is critical and essential to the process as a whole and its urgency required. Moreover, reverse logistics is quite effective at the point where there is the accuracy of information, which can flow either from both, sides that are, forward and backward. In addition, these two points, therefore, it will be probable to note as well as detect the faults/defective products when they enter supply chain because of the pullback of products within supplies.

3.4 Management of reverse logistics

Most companies, which deal with forward-thinking ideas, always try to consider reverse logistics too in their processes. Thus, with the high time, capital spent and attention spent towards the exploration of new idea and concepts, ideally, something left to think of is simply under controlled and even overlooked within such organizations (Fleischmann, 2000). Consequently, when company view reverses logistics, they would see it has a process that covers a wider array of services, which range from just repairs, inspections, redesigning, upgrades, remanufacturing and recycling of the consumer has returned products within the organization. Such reverse process tries to minimize the ancillary cost and waste, generating new revenues streams and offering the best sustainable practices where the company can use outsourcing the management technic of lifecycle and the use of inbound routing guides to manage the process.

Preferably, reverse logistics becomes more and more essential when the budget cinches, bottom line drops and most of the sales grow sluggish as well as when the customer services and economy became paramount (Kleber, 2006). Within an organization or a company, manufacturers would be challenged to maintaining the higher cost of structures without falling loss of risk sales because of having poor customer services. In addition, the retailers, on the other hand, ought to maintain focus on outward forecast look to match the sales efforts and marketing demands. Furthermore, returns and overstock regularly are unavoidable and this would lead to a considerable expense. In order to manage such problems, companies rewire internal infrastructure besides working with partners associated with logistics to manage reverse processes and other related undertakings like having complete reverse outsourcing logistics in minimizing fixed cost/prices.

To begin with, companies manage reverse logistics problem through employing demand and supply plan methodology, which subsequently minimize inventory through ideally postponing such things as unnecessary repairs, and rather focus on repairing activities, which would meet the project necessary for the specified units (Dyckhoff, Lackes & Reese, 2004). In addition, the idea of integrating the returning process and the repair activities/operations at great will reduces the reverse cycle. To control such efficiency, most companies would centralize and increase the control of returning processes thereby enabling the visibility of all inventories all over the reverse cycle. Therefore, purges unnecessary investment received from systems and buildings that try to manage reverse logistics.

Another instance for companies trying to manage reverse logistics is set at a point when it sells its material handling equipment, warehouse and making for outsources on inbound and outbound of the distribution channels towards a third party tier on logistics providers (Dyckhoff, Lackes & Reese, 2004). From this management point of view, they would be a reduction of warehouse labor and footprint which require higher percentage, plus automating the processes whereas, improving on space usage. All the capital gain and recovered are invested in trying to grow the business for a better future ahead.

Finally, companies would opt for working with various logistic providers in managing networks who would identify the key elements based on returns required when trying to improve the products/items (Bonev, 2012). Therefore, the most business process would change and thereby make the company increase on its visibility to try part on hand for field services operators who radically are set to reduce costs and generally centralize each reverse return to have a single location suitable for effective and efficient control within the organization with the logistics management.

3.5 Reverse Logistics and Closed Loop Supply Chains

The idea of reverse logistics and the closed loop supply chain over years have been given great attention to both businesses and markets models. The reasons why such recognition is because this to the process has brought about increased value in technology and products, which have been made directly in the supply chain in most companies are the world based on their impacts. It is to be noted that the concern and problem of the ultimate disposal of trash, scrap, and waste have over time has been a problematic issue within urbanization as its function as well as the increased population density around the metropolitan area (Blumberg, 2005). Industries revolutionizing has brought with its problem of which have increased and intensified because of harmful materials together with the environmental impacts, which are based on growing need to manage and dispose of animal and human waste in protecting safety and health with countries and organization around the world. For years now, companies have brought about a new array of goods and services that have completely ended the traditional direct supply chain whereby such have included:

a) Products those can be reused and repaired

b) Those that are obsolete

c) Goods and products that are able to be recalled

d) Finally, subassemblies and parts that are created by replacing and pull and repaired thus retain the value

Therefore, the idea of this product, items, subassemblies generally has rapidly represented the value and helped in the economic growth towards the end of the supply chain (Coyle & Coyle, 2009). Both reverse logistics and closed loop supply chain process have helped towards the realization of economic value that is quite critical in the aid of environmental concerns.

When it comes to their definitions, reverse logistics as seen above refers to supply chain process of transporting and moving of goods from the final destined point in to order to restore or capture its proper disposed value. On the other hand, closed loop supply chain simply refers to designing and managing both the explicitly of reverse and forward flow of activities in the supply chain (Coyle & Coyle,2009). Like it is suggested from many scholarly book and journals, the two terms are interchangeable and are synonyms though they do have quite some differences. The suggestion is true in that, on reverse logistics the process involves bringing back and forth of used and new items/products for refurbishment, salvage, resale, reuse, and repairs as well as other recycles. Here the on reverse logistics, items would usually be sent to a centralized place for dispensation or processing. In addition, at the point, the process would involve receiving, transportations, inspections, testing, sorting inappropriate manner (Lebreton, 2007). Such facility may be offered to a third party tier in logistics who is linked to the process of the company. Additionally, reverse logistics processes are independently done with the original retailer and manufacturer, that is, this structure is managed and designed for reverse and forward flow.

On the other hand, closed loop supply chain is different from reverse logistics in that it is designed as well as managed for both flows. Contrary to the reverse logistic, closed loop manufacturers are quite proactive in their processes and they are set to capture the value and reduce cost (Lopez & McKevitt, 2018). Both processes ultimate goals are set to recycle and reuse waste products/items. Concisely, to keep our environment safe and secure from pollution, organization senior-most managers are supposed to ensure that they bring about the implementation of processes such as reverse logistics and closed loop supply chain within to help dispose and recycle of goods and products within the organization and thereby enriching an eco-friendly system. Additionally, with such implementations, organizations may as well profit from the resale, recycle, and reuse of products, thereby succeed, and achieve their competitive advantage within the markets and businesses (Ferguson & Souza, 2010). Remember that, customers would always desire the best out of the organization in terms of standardized products, quantity and quality, fair pricing based on desired goods and services and as such, company/organizations should always try to satisfy customers through such supply chain processes. Finally, companies/organizations should always try to find value in dying/dead products, like prioritizing this idea too because of the organization sustainable economic benefits.

Question 4

“Standardization of work is made plausible through use of a WMS” Explain this statement. There are several economic benefits associated with the use of a WMS in large warehousing environments. Identify and briefly explain these.

4.1 Warehouse Management System

Warehouse Management Systems is described as the process of warehousing operations and the superior technologies, which optimize the functions, constituted in a warehouse. Ideally, these functions start at the point of issuing receipt from the trader and ends up with the consignment customers where there is a movement of inventories as well as information flow (Rozanski & Woods, 2011). In order to get a successful warehouse management system results, it is important to design it with both computer hardware and software together with the peripheral equipment containing advance-operating practices for space, inventory, labor management, capital equipment in the distribution of warehouses.

Warehouse Management systems can be defined as the highly specified business use whose purpose enables the control flow of inventory in and around the company supply center. It is typically an application controlling the inventory based on the warehouse with the supply center. Most of the warehouse systems track inventory through real-time and discrete location, that is, understand where all goods/items and products are situated any time (Hompel & Schmidt, 2007). Additionally, any type of warehouse system has sufficiently independent generally with clear set responsibilities/tasks. In addition, the efficiency in solving and tackling the problem is understood through having a rational organization within an intra-warehouse process.

The idea of logistics functions offers fundamental new prospects toward the rationalized warehouse practices. To begin with, most of the warehouse is made or designed to relate to the part of the overall process of goods flow. Here the requirement is communicated after which there are formulated based on the authentic warehouse process. Furthermore, logistic optimization towards warehouse process is to plan the whole process. Most of the inconsistency traditionally would happen in a streaming process that it happens in a warehouse that therefore opens resource to increase efficiency by using logistics. Moreover, through having warehouse management system implemented, there would be enhancement/boost in terms of competitive advantage at improving customer’s service, reducing labor cost and raising inventory accuracy as well as improving flexibility and responsiveness.

Operations within the chain leading inside a warehouse may be designed in internal manufacturing processes to function exclusively. Additionally, the technological practices in the warehouse related to material flow requisite to meet ideal limitations in terms of promptness of the process to ensure the cost-effectiveness and the safety of goods. Moreover, the turnover would demonstrate time with which inventory period is available to be resumed and sold. Normative expenses of goods hang on the responsibilities and purposes of the warehouse, regarding delivery of merchandises and some other detached factors.

The quickening of costs is largely safeguarded by the level of workforce efficiency of warehouse labor. The safeguarding of consumer material goods is communicated in reasonable indicators of the extent of commodity damage, and the redeemable of natural loss, and determined by on the technological procedure, the state of the technical and material the base of the warehouse as well as the quality of work of its workforces.

Together, the essential packing for the safeguarding of the quality of properties must be guaranteed. The idea of economic technological procedure and the level of competence of the warehouse are stated in terms of the cost intensity of dispensation a unit of consignment. However, a company can enhance this indicator individual within the outline of optimization of the whole commodity flow system, subsequently from the perspective of logistics; the competence of the technological procedure in any part of the logistics chain is strong-minded by the side by side of total costs for encouraging material flow along the entire chain.

The most common causes for poor competence and value in the warehouse assembly are the shortage of standardization. Having lack of using best practice and sort ideal standard for each procedure that a business can guarantee in several ways achieving the process as workforces.

The best approach to standardize a practice is to use paramount practice with staff to discovery out the ideal procedure concerning quality and competence features. It is vital to pay attention to the staff’s point of view since they are professionals in the warehouse because they will achieve the process time after time on a daily base (Iskakov, 2018). Lacking the participation of employees, standardization will not feel believable. It is also essential to document the whole lot and make a route guide for respectively each warehouse task. Thus, this will make certain that new staffs are continuously being trained in a similar manner. It is a big task to create a process guide but it means the period it will take. Keep informed on changing procedures does not yield so much period.

In addition, trying to avoid sub-optimization through using the labor force optimally and; thereby, recommending the move resources as well as job rotation regularly in the organization. In case the company warehousing managers do that, they will need employees with more multi-competence and from time to time, there possibly will be long period intervals in advance, where an employee in the similar department twice will be required. In a case similar to that, process guides are quite helpful to avoid inferiority deviations (Schuster, Allen & Brock, 2007). For instance, some individuals I encountered in high-ranking positions in logistics have confidence in that standardization is routinely done while employing a Warehouse management system. Nobody can be further wrong. Warehouse management system is a difficult environment and repeatedly they can task in diverse ways (Emmanouilidis, Taisch & Kiritsis, n.d.). It may have all probable consequences if one does not understand what it is all concerned. Generally, it is would be said that it is also more vital to standardize and file all the implemented Warehouse management systems. In manufacture environs, standardization has been employed for a long time where it in the same way important in the warehouse surroundings. Standardization is likewise one of the essential constituents of lean.

4.1.1 Real Life Example

A good example would be RedPrairie, which has been situated as one of the finest breeds in the supply chain, labor force, and all network retail answers for over 35 years around the world. Additionally, this firm has helped place business for the world’s principal corporations on the move like DHL. Moreover, RedPrairie has its existence in approximately over 60,000 customers establishes through more than 50 nations (Globally, Globally, Meryn, Joel Ewanick, Computing & Prospect, 2018). Likewise, RedPrairie works hard concerning meeting its clients’ future and current wants. Here, it employs several supply alternatives, 24/7 processes, client backing, and flexible responsibility surroundings. Finally, its mission is to benefit and ensure distinguishability and association concerning suppliers, producers, retailers, and customers.

4.2 Benefits of Warehousing Management System

A warehouse management system ensures that a company is able to manage its inventory in actual time together with the facts as current as the most recent order, receipt and the movement (Jalalian, 2018). Below are some of the benefits towards the use of Warehouse management systems in large warehousing environments to aid in the economic notion.

Improvement of labor productivity: – The system helps optimizing material flow this is done through incorporating some of the inventory picks in through cross-docking (Mertins, Krause & Schallock, 1999). Here the term cross docking refers to routing process for incoming shipments to the area located closer to outbound shipment docks that help to reduce warehouse managing.

The Reduction of dependency warehouse workforces: – The workforce should implement a comprehensive warehouse system that will help in facilitating standardized inventory locations, picking methods as well as inventory movement in the warehouse (Sullivan, Barthorpe & Robbins, 2010). Furthermore, having standardized systems help in reducing training cost, reliance on informal practices lowering faulty costs.

The reduction of paperwork on inventories: – Management is able significantly to reduce paperwork through implementing real-time warehousing management systems that are based on traditional connections on warehousing operations (Coyle, 2011). Together with ensuring accurate flow of inventory, timely deliveries, and information flow too; for instance, picking tickets, packing lists and receiving reports excreta that should be maintained in hard copies and store elsewhere like in electronic backups.

Improvement of progressive counting: – Most companies use the warehouse management system to obtain significant data such as specific locations, movement frequency, and product data and so on to schedule the personal cycle counts (Coyle, 2011). This type of cycle counts would not only improve their accuracy within the inventory records when planning but also in eliminating the reduction required through completion as well as the physical cost of inventories.

Enhancement of customer services: – Most companies can be more accurate determine in terms of realistic date delivery and product availability through streamlining processes (Richards, 2011). Using warehouse movement system, a company can automatically release back ordered inventory and identify reduce returns because of increase shipping accuracy.

Proper and more efficient use space available in the warehouse: – To minimize safety stock requirement the warehousing system can frequently increase warehousing space through available locating products/items relating to packing, receiving, shipping point and assembly (Logistics management, 2002). This increased efficiency can help in improving productivity and lower inventory holding quite significantly in terms of cost.

Quicker inventory turns: – The warehousing management system can generate to reduced lead-time through improved accuracy and inventory movement on records thus supporting just in time environments and as a result, the need for safety stocks have minimized that increase the inventory turnover as well as the working capital use (Lai & Cheng, 2016).

References

Chand, S. (2018). Purchasing: it’s Meaning, Definition, Importance and Objectives | Material Management. Your Article Library. Retrieved 28 March 2018, from http://www.yourarticlelibrary.com/material-management/purchasing-its-meaning-definition-importance-and-objectives-material-management/27936

Coyle, J. J., & Coyle, J. J. (2009). Supply chain management: A logistics perspective.

In Edquist, C., In Vonortas, N. S., In Zabala-Iturriagagoitia, J. M., & In Edler, J. (2014). Public procurement for innovation.

Lunney, S. (2018). Five Principles for Creating Effective Sourcing Strategies. Mypurchasingcenter.com. Retrieved 28 March 2018, from http://www.mypurchasingcenter.com/purchasing/blogs/creating-winning-sourcing-strategies-part-2/

Lysons, K., & Farrington, B. (2006). Purchasing and supply chain management. Harlow [u.a.: FT Prentice Hall.

Merriam-Webster. (2018). Definition of PROCUREMENT. Merriam-webster.com. Retrieved 28 March 2018, from https://www.merriam-webster.com/dictionary/procurement

O’Brien, J. (2018). Supplier relationship management: Unlocking the hidden value in your supply base. Kogan Page

Parniangtong, S. (2016). Supply Management: Strategic Sourcing.

Pooler, V. H., & Pooler, D. J. (1997). Purchasing and supply management: Creating the vision. New York [etc.: Chapman & Hall.

Rizza, M. (2018). The five secrets of supplier relationship management – Supply Management. Supply Management. Retrieved 28 March 2018, from https://www.cips.org/supply-management/opinion/2015/february/the-five-secrets-of-supplier-relationship-management/

Stolle, M. A. (2008). From Purchasing to Supply Management: A Study of the Benefits and Critical Factors of Evolution to Best Practice.

Turner, R. W. (2011). Supply management and procurement: From the basics to best-in-class. Fort Lauderdale, FL: J. Ross Pub.

Wisner, J., Tan, K., & Leong, G. (2016). Principles of supply chain management. Boston, MA: Cengage Learning.

Aït-Kadi, D. (2012). Sustainable Reverse Logistics Network: Engineering and Management. London: ISTE.

Blumberg, D. (2005). Introduction to management of reverse logistics and closed loop supply chain processes. Boca Raton: CRC Press.

Bonev, M. (2012). Managing reverse logistics using system dynamics: A generic end-to-end approach. Hamburg: Diplomica Verlag.

Coyle, J. J., & Coyle, J. J. (2009). Supply chain management: A logistics perspective.

Dyckhoff, H., Lackes, R., & Reese, J. (2004). Supply chain management and reverse logistics.

Ferguson, M., & Souza, G. (2010). Closed-loop supply chains. Boca Raton: CRC Press.

Fernández, I. (2004). Reverse logistics implementation in manufacturing companies. Vaasa: Universitas Wasaensis.

Kleber, R. (2006). Dynamic inventory management in reverse logistics. Berlin: Springer.

Lebreton, B. (2007). Strategic Closed-Loop Supply Chain Management. Berlin, Heidelberg: Springer-Verlag Berlin Heidelberg.

Lopez, E., & McKevitt, J. (2018). How a closed loop supply chain can help reduce product waste. Supply Chain Dive. Retrieved 29 March 2018, from https://www.supplychaindive.com/news/supply-chain-sustainability-closed-loop-recycling-packaging/434989/

Magazine, R., & Fernandez, I. (2018). The Concept of Reverse Logistics. A Review of Literature | RL Magazine | Reverse Logistics Association. Rlmagazine.com. Retrieved 29 March 2018, from http://rlmagazine.com/edition58p40.php

Niroomand, I. (2018). The Importance of Reverse Logistics – Kinaxis. The 21st Century Supply Chain. Retrieved 29 March 2018, from https://blog.kinaxis.com/2017/09/importance-reverse-logistics-supply-chain-network/

Robinson, A. (2018). What is Reverse Logistics? Is It Different than Traditional Logistics?. Transportation Management Company | Cerasis. Retrieved 29 March 2018, from http://cerasis.com/2014/02/19/what-is-reverse-logistics/

Hompel, M., & Schmidt, T. (2007). Warehouse Management: Automation and Organisation of Warehouse and Order Picking Systems.

Coyle, J. J. (2011). Transportation: A supply chain perspective. Australia: South-Western Cengage Learning.

Emmanouilidis, C., Taisch, M., & Kiritsis, D. (n.d.). Advances in Production Management Systems. Competitive Manufacturing for Innovative Products and Services [recurso electrónico]: IFIP WG 5.7 International Conference, APMS 2012, Rhodes, Greece, September 24-26, 2012, Revised Selected Papers, Part I.

Globally, D., Globally, D., Meryn, R., Joel Ewanick, M., Computing, M., & Prospect, T. (2018). DHL To Standardize Warehouse Operations Globally – Industry Leaders Magazine. Industry Leaders Magazine. Retrieved 29 March 2018, from https://www.industryleadersmagazine.com/dhl-to-standardize-warehouse-operations-globally/

Iskakov, Y. (2018). Logistics management. Academia.edu. Retrieved 29 March 2018, from http://www.academia.edu/33188661/Logistics_managment

Jalalian, M. (2018). 10 Ways a Warehouse Management System Pays for Itself – MSA Systems, Inc. MSA Systems, Inc. Retrieved 29 March 2018, from http://www.msasys.com/10-ways-a-warehouse-management-system-pays-for-itself/

Lai, K., & Cheng, T., (2016) Just-in-time logistics.

Logistics management. (2002). Highlands Ranch, CO: Reed Business Information.

Mertins, K., Krause, O., & Schallock, B. (1999). Global Production Management: IFIP WG5.7 International Conference on Advances in Production Management Systems September 6-10, 1999, Berlin, Germany. Boston, MA: Springer US.

Richards, G. (2011). Warehouse management: A complete guide to improving efficiency and minimizing costs in the modern warehouse. London: Kogan Page.

Rozanski, N., & Woods, E. (2011). Software systems architecture: Working with stakeholders using viewpoints and perspectives. Boston, Mass: Addison-Wesley.

Schuster, E. W., Allen, S. J., & Brock, D. L. (2007). Global RFID: The Value of the EPCglobal Network for Supply Chain Management. Berlin, Heidelberg: Springer-Verlag Berlin Heidelberg.

Sullivan, G., Barthorpe, S., & Robbins, S. (2010). Managing Construction Logistics. New York, NY: John Wiley & Sons.

Council of Logistics Management (1991) “Definition of Logistics”.

Tilanus, B. (1997) “Information Systems in Logistics and Transportation”. Elsevier Science Ltd., UK.