Abstract

The following experiment was conducted to investigate the effects of different types of sugar on the effects of carbon dioxide production. The hypothesis is that the volume of CO₂ produced would be significantly different for each sugar. The upward displacement method was used for the collection of gas over water. The carbon dioxide readings were taken every 2 minutes, and the experiments were run for 20 minutes. The sugars used were glucose, fructose, sucrose, and lactose. 5 grams of yeast was used with 50 ml of water. 100ml of 0.5 mole/dm3 of each sugar solution was used with the yeast. The results showed that glucose was the most efficient of all the sugars as it produced an average of 115 cm³ of CO₂ with yeast. According to the experiment, the sugars were efficient in the order of glucose, sucrose, fructose, and lactose. Lactose was the least efficient of all the sugars as it only produced an average of 19 cm³ in 20 minutes in the yeast mixture. The yeast might have been unable to synthesize lactase to break down lactose in glucose and galactose. It was unclear in the experiment whether the CO₂ was formed during oxidative phosphorylation or during fermentation.

Introduction

Fermentation is a biological process that occurs when yeast breaks down sugar, producing carbon dioxide and ethanol. This is seen through observing gas bubbles rising to the top of a fermentation tube and measuring the results. Though alcohol is present, it is difficult to measure, so for the experiments shown below, all fermentation reactions were measured by the production of carbon dioxide (CO2). Yeast mixed with sugar produces gas bubbles of CO2. This alcohol is proportionately produced at the same level as CO2. The reaction will stop after time, though it can begin again with the addition of more sugar. Therefore, we can summarize that fermentation is yeast + sugar = CO2 and alcohol. Fermentation is important as it produces many products that people consume today, such as alcohol, bread, or kimchi. Fermentation is also important as it shows that a substance, yeast, consumes energy and glucose and produces gas, CO2, and alcohol (Jones, 1963).

Research question

How does the type of sugar affect the rate at which CO₂ is produced by yeast?

Hypothesis

- The rate of CO₂ production is significantly different for each sugar.

- The release of CO2 will change due to the yeast oxidized to carbohydrates in a different way due to the fact that the links between the saccharides are different and the enzymes that produce only can oxidize carbohydrates specifically so it is possible that some of the substrate employees cannot be metabolized by S. cerevisiae.

Background information

Fermentation is a set of chemical reactions carried out by living and non-living elements through which an organic compound is oxidized partially in the absence of oxygen to obtain chemical energy, understanding how partial oxidation occurs when all the carbon atoms of the compound are oxidized to form CO2.

According to this, the fermentations were classified on the basis of the products that are obtained by the transfer of power reducer to organic compounds. Some examples of fermentations are the following: homoplastic fermentation, which produces lactic acid, alcoholic fermentation to produce ethanol and CO2; mixed-acid fermentation which occurs in the acetic acid, succinic acid, ethyl acid, CO2, and water; the fermentation propiónica produces propionic acid, acetic acid and CO2; fermentation of the butanediol that produces ethylene glycol and CO2; and the butiricabutilica fermentation that produces butyric acid, butanol, isopropyl alcohol, ethanol, and CO2 (Angustia, J., Chan, M., Dinneen, D., Hortamani, S., & Mutabaruka, D. 2014).

The yeast used in this experiment is known as Saccharomyces cerevisiae. It, better known as brewer’s yeast, is a single-celled fungus that has been used for more than 250 years for the production of beer, wine, and bread. This yeast is able to survive along two pathways: one of them is fermentation, in which the yeast is out of contact with oxygen, obtaining the necessary energy to carry out their vital processes from metabolizes carbohydrates to producing ethanol and CO2. This yeast requires that glucose is catabolized by glycolysis or Embden-Meyerhof path for the pyruvate, which subsequently, by the action of specific enzymes, it is converted anaerobically in ethanol and CO2.

The yeast forms colonies of cream or white, wet and shiny appearance with irregular edges. The optimum temperature for growth is 25 to 30 °C. You can produce ascospores when there are adequate nutritional requirements. (Chen, Y., Krol, J., Huang, W., Mirro, R., & Gossain, V. 2008).

The literature describes two types of Respiration Aerobic Respiration. The general equation for anaerobic respiration of yeast is:

C6H12O6 → 2C2H5OH + 2C02

This process only involves glycolysis. Where glucose is not completely broken down, and the end products are ethanol, carbon dioxide, and a small amount of energy (Chen, Y., Krol, J., Huang, W., Mirro, R., & Gossain, V. 2008).

The general equation for the aerobic respiration of yeast is:

C6H12O6 + 6O2 → 6 CO2 + 6H2O.

However, this equation involves several processes, i.e., glycolysis, Krebs cycle, and the electron transport chain. In aerobic respiration, glucose is completely broken down and the end products are water, carbon dioxide, and a large amount of energy.

Monosaccharides have the formula: C6H12O6, and disaccharides have the formula: C12H22O11. Monosaccharides have a smaller molecular mass than disaccharides. However, monosaccharides are more soluble in water than disaccharides. Two monosaccharides combine to form a disaccharide with the formation of an ester bond between the hydroxyl groups in a condensation reaction. The bond that forms between the monomers is called a glyosidic bond. Some organisms are more efficient at getting energy from different forms of sugars due to the enzymes they use. Therefore I aimed this experiment to investigate the sugar that works best with yeast. The yeast may be compatible with one type of sugar but not the other (Angustia, J., Chan, M., Dinneen, D., Hortamani, S., & Mutabaruka, D. 2014).

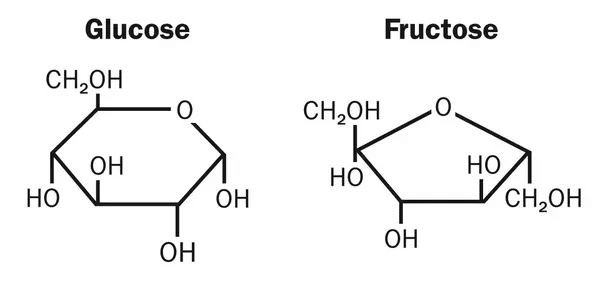

Figure: the structure of glucose and fructose (monosaccharides consumed during the experiment)

This experiment was intriguing to me. Following my mom’s recipe, when I make doughnuts have to soak the yeast in lukewarm milk with sugar for a few minutes. It fascinated me why yeast always has to be combined with milk and/or sugar before use. I observed that the yeast produced more bubbles when coupled with milk and sugar as compared to the yeast with only milk. Milk contains lactose, whereas table sugar is sucrose. This was interesting to me as the internal assessment gave me a chance to investigate this further. For my internal assessment, I wanted to investigate the amount of carbon dioxide produced with different sugars and hence discover the sugar that works best with yeast. I chose the upward delivery method as I have had experience with this technique. It is a convenient and efficient way to collect carbon dioxide gas (SS and VA, 2016).

Objectives

- To quantify with the help of laboratory apparatus the CO2 generated from the fermentation process of the different types of sugars.

- Analyze the differences in the release of CO2 for all four types of sugars by the process of fermentation.

- Understand the process of anaerobic respiration carried out by yeast in laboratory conditions.

Methodology

This research has arisen due to a problem in biology class, which was raised to S. cerevisiae (Yeast) with a substrate of carbohydrates such as maltose with the objective of fermenting this disaccharide, resulting in the production of alcohol. At this time, the question came up if only maltose yeast could get the energy to survive. It is for this reason that it was thought to experience bringing people into contact with the yeast with other carbohydrates.

As already mentioned in the introduction, alcoholic fermentation produces CO2 and ethanol. Considering this, in the experimental design is to use a total of four substrates: Glucose, maltose, sucrose, and fructose, with the purpose of showing which of these substrates the yeast makes a more efficient energy transformation and produces more Carbon Dioxide. For the above was used as a parameter, the release of CO2 considering it proportional to the amount of substrate metabolized by the yeast.

Independent variable: Sugar Type.

Dependent variable: Quantity of CO2 produced in 20 minutes.

Apparatus

- Flask

- Beaker

- Measuring cylinder

- Analytical balance

- Rubber delivery tube

Chemicals Used

- Yeast- S. cerevisiae

- Water

- Types of sugars;

- Fructose (monosaccharide)

- Sucrose (disaccharide)

- Glucose (monosaccharide)

- Lactose (disaccharide)

Applications of the products of fermentation in the food industry

It is understood that alcoholic fermentation is the quantitative transformation of glucose into ethanol and CO2. More strictly refers to a biological process of fermentation in the absence of oxygen, caused by the activity of some microorganisms that process the carbohydrates for how end products: alcohol in the form of ethanol, CO2 in the form of gas, and some molecules of ATP to consume the micro-organisms themselves in your anaerobic energy metabolism. The resulting ethanol is used in the production of alcoholic beverages (Angustia, J., Chan, M., Dinneen, D., Hortamani, S., & Mutabaruka, D. 2014).

The beer is prepared by ethanol fermentation of carbohydrates present in the grains of barley by glycolytic enzymes of yeast. The glúcidos ones, basically polysaccharides, must be previously degraded to mono and disaccharides by enzymes such as amylase and maltase. The yeast cells metabolize sugar anaerobically and ferment sugars to ethanol and CO2. Once that has stopped, the fermentation is separated from the cells, and the “raw” beer is ready for the final treatment (Batista AS, Miletti LC, Stambuk BU. 2004).

Saccharomyces cerevisiae, better known as brewer’s yeast, is a single-celled fungus that has been used for more than 250 years for the production of beer, wine, and bread. This yeast is able to survive along two pathways: one of them is fermentation in which the yeast is out of contact with oxygen, obtaining the necessary energy to carry out their vital processes from metabolizing carbohydrates, producing ethanol and CO2 (Peters 806-814).

Procedure

In the beaker, 5 grams of yeast was added to 50 ml of water at 40 degrees. This is a suitable temperature for the yeast to activate. An analytical balance was used to measure elements throughout the experiments. The mixture was left to rest for 5-7 minutes for the yeast to activate. 0.5 molar solutions of glucose, fructose, sucrose, and lactose were prepared at room temperature. This would be a suitable concentration to investigate the amount of CO₂ produced from different types of sugars. 100 ml of each solution was added to multiple mixtures of yeast and water. The carbon dioxide produced during the respiration of yeast with the sugar was measured. The upward displacement method over the water was used for the collection of carbon dioxide as it is not very soluble in water. A measuring cylinder (250 cm³) full of water was inverted underwater in a 1000ml beaker to make sure that there were no air bubbles inside the cylinder. One end of a rubber delivery tube was inserted into the cylinder, with its other end in the flask containing the yeast and sugar mixture. This method is a reliable technique for the collection of gas, it does not include any sophisticated equipment with less probability of error, and I have had experience with this method in the past. The experiment was conducted for 20 minutes, and the carbon dioxide readings were taken at two-minute intervals. Every experiment with different sugars was carried out at least two times for reliable results. The yeast was allowed to react with the air in the flask. I also conducted a control experiment to compare with the findings of my experiments. The control experiment consisted of 5 grams of yeast in 50 ml of water.

In Figure 3, the flask containing the yeast and sugar mixture is connected to an inverted measuring cylinder for the collection of gas over water.

The experiment was conducted at room temperature, controlled between 20 – 22 degrees. The type of yeast was constant ( Idun Gjaer original). Before each experiment, the yeast was allowed to be activated for about 5 minutes. Each mixture of yeast was mixed with water at 40 degrees. The water used during the experiment was from the same source (tap water). The length of the delivery tube was kept constant in all the experiments. The size of the flask was also kept the same in every experiment. Each reading for carbon dioxide was taken after two minutes. The analytical balance used during the experiment was also kept the same.

Ethical Implementation

The ethical guidelines of the IBO were met. Protective gear was worn, such as safety goggles and gloves throughout the experiment. Safety precautions were met; the glassware was handled with care. The sugar and yeast mixture was disposed of properly after the experiment. No harm was done to any living being/creature during the course of this experiment.

Results

The results are presented below in the form of tables and graphs. In Figure 5, a gradual increase in the rate of reaction can be expected as the sugar reacts with the yeast. The mean of all the readings was put on a bar graph (figure 6). A standard deviation could not be calculated as only two experiments were conducted for each sugar. Different colors are used to illustrate the different sugars. Blue for glucose, maroon for sucrose, green for fructose, and yellow for lactose. I put the points in Figure 5 to show the range of the gas produced.

Exp 1 denotes all the data collected in the first experiments, and Exp 2 denotes all the data collected in the second experiments for the sugars. The mean shows the average amount of CO₂ of the two readings.

The above chart displays the average records of the concentration of CO2 released by the anaerobic metabolism of S cerevisiae exposed to all four types of sugar. This graph shows that substrate glucose reached 100+ ml CO2/min concentration. However, other substrates such as Fructose, Sucrose, and Lactose reached lower values, 56.5, 68.5, and 19 ml CO2/min, respectively (Peters 806-814).

We can point out that the Glucose substrate is efficiently metabolized by the yeast used in the present study. Also, substrates such as lactose, fructose, and sucrose are used appropriately by the yeast. However, the metabolic efficiency of fructose is low according to the results obtained for this substrate. And almost “null” for the substrate of lactose under the experimental conditions employed.

The experiment was done twice for each substrate to release CO2 during the fermentation process. This made it possible to calculate the average of both records and thereby reduce the standard error in our study. Figure 5 and Figure 6 clearly show a difference in the carbon dioxide produced by the different sugars. Hence the hypothesis is supported. The independent variable did have an effect on the dependent variable. Figure 5 shows a gradual increase in the production of carbon dioxide with the progression of time. Glucose produces the highest amount of carbon dioxide than any other sugar. In comparison to glucose, sucrose produced just a little over half of the gas, fructose produced about half, and lactose produced about a quarter of the amount of carbon dioxide as compared to glucose (Dyke, 1960).

The results form a pattern with an increasing gradient which shows an increase in the rate of production of carbon dioxide. Figure 5 compares the difference in the rate of production of CO₂ whilst Figure 6 illustrates a difference in the average amount of CO₂ produced by each of the sugars. Figures 5 and 6 illustrate that glucose was the most efficient with yeast as it produced the highest volume of carbon dioxide than the other sugars. Figure 5 also represents the rate of reaction for each of the sugars. Glucose had the highest rate of reaction, and fructose and sucrose had a very similar rate of reaction.

However, lactose had the slowest rate of reaction and managed to produce the least amount of CO₂ than any of the other sugars. Figure 6 denotes a considerable difference in the average amount of CO₂ produced by each sugar. The propositions as to why the sugars produced such varying amounts of CO₂ are discussed in the evaluation. The graph does not become constant at the end; this suggests that the reactions were incomplete, as the yeast and the sugars were still reacting to produce CO₂. Therefore, the pattern cannot be fully studied and is not completely reliable. From Figure 5, it can be deduced that sucrose had the highest and lactose had the lowest range than any of the other sugars. A noticeable pattern between the monosaccharides and disaccharides cannot be studied from the data collected. The control experiment did not produce any changes.

Limitations

The results may not be as reliable due to certain limitations. The yeast might have required more or less time to activate. There might be errors in the readings, e.g., parallax errors which may affect the results; there might be errors when weighing the yeast and sugars. The air inside the flask may have affected the results, and some of the CO₂ produced by the yeast may have been absorbed in the water hence affecting the results. The carbon dioxide produced might not have been consistent. The yeast might have required higher or lower temperatures to be properly activated. There may be a chance that some of the CO₂ may have leaked from the delivery tube hence altering the results. The air inside the flask may have been used up by the yeast, and it may have started to respire anaerobically.

The results may have also been affected by the length of the delivery tube. Some of the air might be inside the flask. The experiments were not repeated multiple times to obtain an average, which reduces the reliability of the data collected. The time of the experiment might not have allowed the yeast to reach its maximum respiration rate. The probability of these errors lowers the reliability of the results; however, these can be overcome by certain measures which are discussed in the evaluation.

Evaluation

Figures 4 and 5 clearly suggest a difference in the mean carbon dioxide produced by the different sugars, thus supporting the hypothesis for this investigation. Although both fructose and glucose are monosaccharides and share the same chemical formula, they did not produce similar amounts of carbon dioxide; fructose produced 56.5 cm³, whilst glucose produced 115 cm³. The graphs indicate an increase in the volume of carbon dioxide produced by sucrose (68.5 cm³) than lactose (19 cm³), despite the fact that they both are disaccharides and share the same chemical formula. However lactose is a reducing sugar, but sucrose is not. The aldehyde group in lactose can be oxidized to form a carboxylic acid. The yeast might not possess lactase which breaks it down into glucose and galactose.

Glycolysis requires glucose as a reactant, whereas the sugars (except for glucose) had to be converted for them to be used in glycolysis. Sucrose had to be broken down into fructose and glucose; lactose had to be broken down into glucose and galactose. The fructose chain had to be altered to be used in glycolysis. These changes may be used to explain why these sugars were not as efficient as glucose in the production of CO₂. From the results obtained in the control experiment, it can be said that yeast cannot respire without the presence of sugar, which serves as an energy source (Batista AS, Miletti LC, Stambuk BU. 2004).

The concentrations of each sugar were 0.5 mole/dm³. Therefore, the energy supplied to the disaccharides and the monosaccharides differ. The energy supplied to the disaccharides was about three times the energy provided to the monosaccharides. However, the disaccharides failed to produce more carbon dioxide than glucose. Lactose produced almost a quarter of the carbon dioxide as glucose despite receiving almost three times the energy. Within the scope of this exploration, it was difficult to determine whether the carbon dioxide was produced during oxidative phosphorylation in aerobic conditions or during fermentation in anaerobic conditions (Morton, J. S. 1980).

To obtain more accurate results and overcome the errors (discussed in the analysis) in the experiment, more experiments have to be conducted to calculate the mean of all the readings. To determine the accurate effects of the difference in the rate of respiration of yeast with different sugars, more types of sugars might provide precise results for conclusions to be made. Accurate equipment should have been used for more exact results. A glass delivery tube could have been used for protection against leaking instead of a rubber tube. The temperature of the water could have been tightly controlled to minimize the solubility of carbon dioxide. The readings could have been taken more frequently to study the pattern in detail. Fresh yeast could have provided more reliable results. A consistent oxygen supply could have ensured that the yeast only respires aerobically. The experiment should have been run for a longer time as the maximum rate of respiration could have been studied. A glass syringe could have been used for the collection of gas, which would eliminate the possibility of the absorption of gas into the water hence providing accurate results (Huxley, 2008).

Conclusively it can be said that yeast has a higher affinity for glucose than any of the other sugars used in the experiment. A higher affinity means that less substrate was required by glucose as compared to the other sugars for a rate of reaction to be observed.

Analysis

The release of metabolic waste CO2 from the fermentation helps us to understand the operation of this metabolic process in S. cerevisiae, as this product evidences the amount of substrate fermented by yeast, which offers valuable information about the food that promotes the growth of this organism. Then, observing the graphical results, one comes to a head one question: being that all carbohydrates contain glucose, why is there such a difference between glucose and lactose intolerance?; and without going any further, why is there a considerable difference between glucose and fructose? Well, the difference is, for the most part, in the glycosidic bonds of disaccharides, enzymes in the yeast, and some agents that are present in the molecule of carbon hydrates.

Looking at the difference between glucose and lactose. It is required to understand that these two carbohydrates come from the treatment of sugar cane. The glucose is obtained by dehydrating the molasses from the sugar cane and then grinding the solids obtained. The calorie amount between glucose and fructose is very small; for every 10 grams of sucrose are obtained, 36 calories, while for the same amount of fructose are obtained 33 calories. This may be an indication that the structures of both are virtually the same.

Then the difference is in the process of refining the molasses (extract from sugar cane). It should be noted that this process is what you are looking for is to remove impurities in this extract with the aim of producing almost 100% sucrose. This is where lies the difference; these “impurities” are more nutrients, enzymes, and vitamins, which according to nutritionists, helps to better digestion and utilization of calories from carbohydrates. Another important thing that should be taken into account is the process that S. cerevisiae performed to ferment the wide range of carbohydrates that are attributed to him.

Conclusions

After working with the experiment, understanding the metabolic behavior of the yeast and analyzing their efficiency in assimilating certain carbohydrates. Indeed, S. cerevisiae is able to use various substrates such as fructose, glucose, sucrose, and lactose for producing carbon dioxide. The measurements were made with an experimental design that was used to collect and measure the CO2 emitted from the fermentation of each substrate at a concentration of 10%. The results obtained showed that glucose generates the maximum amount of CO2 upon fermentation by the yeast as compared to other types of sugar. It was observed that the fermentation generated minimum CO2 for lactose. It is concluded that the observed differences in the metabolism of the different substrates originate in the molecular structure and the presence of vitamins and enzymes that are present in some of them.

Bibliography

Angustia, J., Chan, M., Dinneen, D., Hortamani, S., & Mutabaruka, D. (2014). The effect of different sugars in the medium on carbon dioxide production in Saccharomyces cerevisiae.

Batista AS, Miletti LC, Stambuk BU. Sucrose fermentation by Saccharomycescerevisiae lacking hexose transport.J Mol Microbiol Biotechnol. 2004; 8(1):26-33.PubMed PMID: 15741738

Chen, Y., Krol, J., Huang, W., Mirro, R., & Gossain, V. (2008). Anaerobic yeast fermentation forthe production of ethanol in a versatile lab fermentor. Nature Methods, 5, 4-5. Retrieved from http://www.nature.com/nmeth/journal/v5/n12/full/nmeth.f.228.html

Dyke, S. (1960). The carbohydrates. New York: Interscience.

Huxley, T. (2008). Yeast. [Place of publication not identified]: Dodo Press.

Jones, M. (1963). A bibliography of publications on the chemistry and technology of sugarcane and sugarcane products. New Orleans: Southern Utilization Research and Development Division.

Morton, J. S. (1980). Institute Creation Research. Glycolysis and Alcoholic Fermentation.

Peters, D. (2006). Carbohydrates for fermentation. Biotechnology Journal, 1(7-8), pp.806-814.

SS, K. and VA, A. (2016). Enzyme-Modified Screen-Printed Electrodes for Assaying Glucose, Ethanol, Lactate and Starch in Fermentation Media. Fermentation Technology, 05(01).

Utomo, R. (2014). Effect of Sucrose Concentration on Cell Respiration in Yeast.