Current Advances in process temperature measurement: trends and technologies

Thin-film resistance temperature detectors are devices that are used in measuring temperature in Chemical process industries. The temperature measurement device is important since improves the processes in chemical industries. Therefore, it used in critical parts of processing, for instance, it is used in measuring temperatures in the reactors, boilers, heat exchangers and evaporators processing. The market for these technologies continues to revolutionize due to technological advancement. At personal level one can use portable mercury temperature sensor as a device used for noting the temperature changes. It helps in creating health awareness to an individual who uses them; thus, helps individuals in making a healthy decision and deal with temperature related-issues. After the time, the temperature is second most measured data. Therefore, the measurement of the temperature goes way back to 2nd Century. Therefore, people have already known that expansion occurs due to heat while contractions occur due to cold. The technological growth of the devices used in measuring temperatures has experienced rapid growth over time. In the year 1998, the most common temperature device used at the time was mechanical type sensors. The mechanical temperature sensor depends on the expansion and contraction of liquid, solid or gases substance to determine and measure temperature changes. The most common mechanical temperature sensor is mercury temperature sensors since it uses contraction and expansion of liquid to show changes in temperature. But for the purposes of this discussion will use the thin-film resistance temperature detectors technology.

The most measured variable in chemical process control is temperature. Therefore temperatures devices are revenue is approximated to be $400 million and 30% going towards chemical process industries in the United States alone (Cushing, 2017). Over the years, the chemical process industries have experienced technological advancement in sensors. Due to accuracy issues, cost and high maintenance cost the industries have shifted to using resistance temperature detectors (RTDs) instead of the commonly used Thermocouples (T/Cs). The development of the RTDs technology will enable users to measure the temperature values accurate. Also, the technology offers more stability. The thin-film RTDs technology development has the desire to reduce costs and improve operation (Cushing, 2017). Therefore, the technology will replace the use T/Cs and also increase the availability of temperature integrated assemblies. The new technology is designed to solve problems associated with the temperature process in chemical process (Cushing, 2017). The technology will help in decrease wiring costs, reduce hardware and increase efficiency and accuracy, easing future upgrades and also help in simplifying engineering by preventing wiring mistakes.

The process of the RTDs in order to achieve ultimate accuracy, the user can depend on two available options. First, to sensor matching from the RTD you can use Callendar-Van Dusen (CVD) data and the second one can change CVD data to avoid errors in the transmitter (Cushing, 2017). This technology offer high-accuracy RTD includes:

- Choosing the element results in high-purity platinum, which ensures highest accuracy and stability.

- Also, it has the ability to reduce self-heating effects.

- RTD is not connected to a specific transmitter. This aspect ensures RTD, transmitter and sensor are flexible.

- Increase time efficiency.

- The technology reduces and eliminates the costs related to VCD calibration.

- The technology offers the best accuracy and reliable point of measurement.

Part 2

Predictions: Cone of Uncertainty

Uncertainty

Achieve 100% accuracy level

50% of CPI will use the Resistance Temperature Detectors

Accuracy level 99.9% and gain attraction

2019 2023 2028 Time

High Accuracy the Resistance Temperature Detectors

Integrated Assemblies for process temperature measurement

Uncertainty

Short-term: Guaranteed level of accuracy of 99.9% and Market Attraction

Time-Frame: 2019

Level of Certainty: Relatively certain

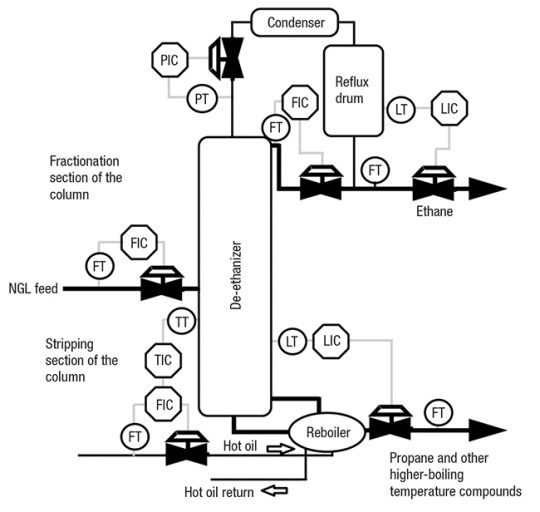

We forecast that by 2019; the technology behind the resistance temperature detectors will have gain market attraction and penetrated in the market by approximately 30%. Also, the technology would have been modified to improve its accuracy level. Thus, the accuracy level of the technology would be modified up to 99.9%. With already in use in the market, the technology will help in addressing the problems with existing processes of temperature measurement in the chemical process industries. The growing popularity of the technology in the rise, the chemical process industries will able to reduce the costs associated with the existing process of measuring temperature. By 2019, most chemical process industries in the business, especially in the United States, will have incorporated the technology into their process system. Also, by 2019 will see the RTDs technology being used in different chemical processes. First, the technology will be used in the reactors process, boilers process, heat exchangers and evaporators’ process. Therefore, the technology will improve the processes as well as increase efficiency and effectiveness of the processes. Also, the technology will help in decrease wiring costs, reduce hardware and increase efficiency and accuracy, easing future upgrades and also help in simplifying engineering by preventing wiring mistakes. We certain this level of uncertainty as relatively certain because the technology is already in uses and because we have seen an increase in demand for advanced technology before.

Mid-term: 50% of Chemical Process Industry will adopt use the Resistance Temperature Detectors

Time-Frame: 2023

Level of Certainty: Moderately certain

We predict that by 2023, the technology will be used widely all over the world. Also, 50% of the process temperature measurement in chemical process industries in use will be resistance temperature detectors. Since by then the technology would have proved on how it works it will an imported in various industries which the technology. With the growth in the industry, we will expect the market for the product to have competition. By 2023, the demand for technology will be high, that they will be the entry of new companies with the same technologies leading to the market competition of the technology.

We positioned this prediction at being moderately certain due to some potential factors that could halt the advancements. Also, by 2023 the resistance temperature detectors will incorporate integrated assemblies to increase effectiveness and efficiency of the process of temperature measurement system.

Mid-term: Achieve 100% accuracy level and use High Accuracy the Resistance Temperature Detectors

Time-Frame: 2028

Level of Certainty: Relatively Uncertain

We predict that by 2027, the technology will be improved to achieve 100% accuracy level and the technology will use high accuracy resistance temperature detectors. Even small CPI will adopt this technology due to its high accuracy level. Also, we foresee that the technology will become popular with its consumers, the company providing this technology will partner will other big tech companies to ensure 100% accuracy level. The process of the RTDs in order to achieve ultimate accuracy, the user can depend on two available options. First, to sensor matching from the RTD you can use Callendar-Van Dusen (CVD) data and the second one can change CVD data to avoid errors in the transmitter. This technology offer high-accuracy RTD.

Works Cited

Cushing, Michael. (2017) “Advances in process temperature measurement: trends and technologies” Retrieved from http://www.chemengonline.com/advances-process-temperature-measurement-trends-technologies/?pagenum=2